Introduction:

In Niederberg in North Rhine-Westphalia, GVG Rhein-Erft used hydrogen to supply heat for the first time. 20 per cent has been fed into the gas grid in the Erftstadt district since October 2022. The H2-MiX pilot project is an important step towards a climate-neutral heat supply. GVG Rhein-Erft GmbH and Rheinische NETZGesellschaft mbH (RNG) are in charge of this project. Before the hydrogen feed-in was realised, the project partners examined all materials and components in the gas network and at the residents’ homes in detail. Further details on this project can be found on the website www.h2-mix.de . The project ended in January 2024. The test facility, in which the L natural gas and H2 are mixed, is set up in a container. See photo 1. The hydrogen required comes from gas cylinders. See photo 2.

Project description:

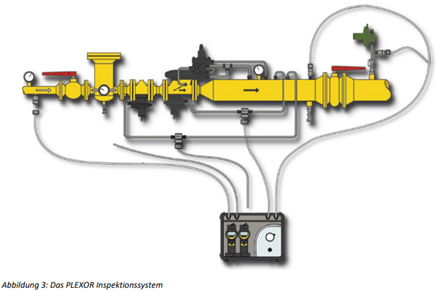

GVG Rhein-Erft has been using the PLEXOR test system from Wigersma & Sikkema since 2007. This system consists of a measuring unit, connection hoses, operating software, and system couplings. The system couplings are permanently mounted in the gas pressure regulator station (and are therefore constantly exposed to the gas) and are used to connect the measuring unit to the gas pressure control line via the connection hoses during functional tests.

Figure 3 provides an overview of the PLEXOR inspection system.

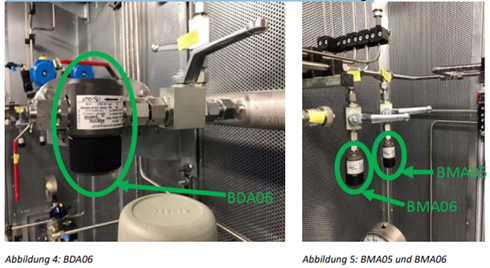

Hydrogen is a key factor for a climate-neutral energy supply of the future. The aim of this project was to test whether long-term exposure to hydrogen under increased pressure would affect the tightness of the system couplings in particular. Three couplings (types BMA05, BMA06 and BDA06) were installed in the hydrogen part of the gas system. They were therefore continuously exposed to 100 % H2 at a pressure of between 10 and 15 bar. See photos 4 and 5.

The BMA05 coupling was removed at regular intervals and checked for leaks at Wigersma & Sikkema. It was then reinstalled in the gas system. The other two system couplings (BMA06 and BDA06) were not tested regularly, but only at the beginning and end of the project.

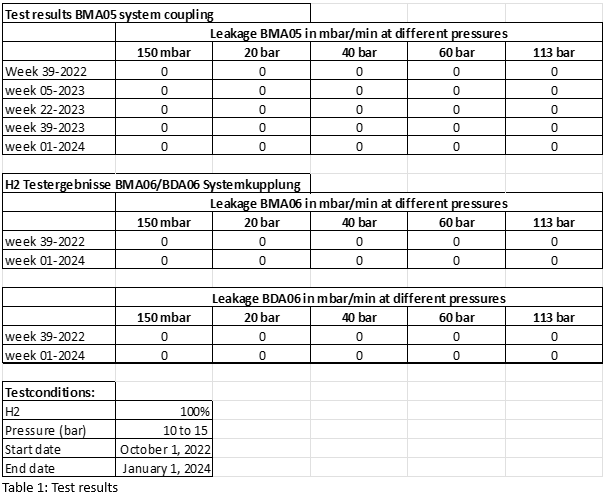

The tightness was tested at various pressures with forming gas containing 5 % hydrogen.

Table 1 shows the test results.

Conclusion:

As can be seen, no leakage was detected at any system coupling. This is in line with the general assumption that all materials compatible with methane up to approx. 60 bar are also compatible with hydrogen.